Older vehicles suffer from a number of issues that lead to dimmer appearing gauges than the day they left the factory. Properly diagnosing what is happening in an older vehicle is the first step in finding a cure for the problem.

Tired Wiring

Older vehicles suffer from deterioration that comes with aging. With use and age, the wiring in older vehicles has become more resistant. As a result, it does not carry current as well as it did when it was new. The reduction in the ability to carry current to the lamps results in the gauge cluster bulbs not lighting to full brightness.

The Dimmer Switch

Along the same lines, the rheostat (dimmer switch) in nearly all older vehicles is restricting current to the lights on the dimmer circuit. This results in the lights not being lit to their full brightness. We recommend that any dimmer switch over ten years old be tested or replaced. In our testing less than 1.5 out of 20 switches over 20 years old work as they should!

Incandescent Bulbs

The nature of incandescent bulbs is another reason that gauges no longer appear as bright. The average life of an incandescent bulb is about 1000-2000 hours. While that may seem like a good life span, it is not an indicator of their performance over their life. Incandescent bulbs produce less and less light as they operate. The longer a bulb is lit, the more filament burns away. As the filament burns away, the bulb produces less light output. Incandescent bulbs continue to “burn” the filament until it gets so thin that it breaks. This is where we get the saying that lights “burn out” when they die. The fact is that by the time an incandescent lamp has burned for 400-500 hours, it is producing less than 50% of the lumens that it did when it was new! By the time a bulbs is approaching the end of its life, it is producing only a fraction of the light that it produced when it was new. In contrast, LED lights have a life of 10,000 hours or more and produce 100% of their light output until the day they die.

Illumination Lenses (Filters)

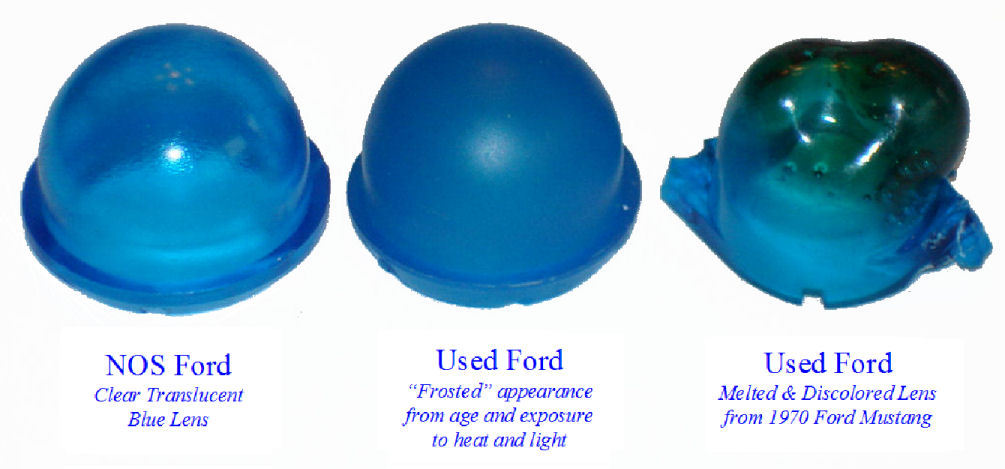

Another symptom of the problem with gauge lights can be attributed to the filters in the gauge cluster. As time passes, the small colored lenses in the gauge cluster that provide color to the gauge lights (normally blue or red) lose their clarity. This can normally be polished out with a simple lens polish, but it is a contributing factor. Changing to LED bulbs with increased brightness helps overcome that slight discoloration in the lenses.

|

In extreme cases, the colored lenses in a gauge cluster have melted or burned. This is normally due to a past owner installing “brighter” incandescent bulbs in the instrument cluster. While this sounds like a viable solution, it is the worth thing you can do. If an incandescent bulb is brighter, then it produces more heat. More heat means damaged and melted parts. Those “brighter” incandescent bulbs also draw more current. In some cases, that additional current draw is enough to damage the wiring. The wiring in most circuits in the car is designed to handle a specific load. Adding an additional load cause damage which leads to a reduction in the wires ability to carry current. This leads to a greater dimming effect in the dash.

The Gauges

Most people do not understand that the design of many vintage gauge clusters was formed around the use of fluorescents. The gauge needles and the characters printed on the face of the gauges were done with fluorescent colors. This made the needles and the print on the gauges “glow” when the lights came on. Unfortunately, fluorescent pigment faded over time. Ultra violet rays cause the pigment to fade long decades before the paint color fades away. In fact, more fluorescent paint has lost all of its pigment after about 10-15 years. The needles can easily be restored using HiPo Parts Fluorescent Speedo & Gauge Needle Paint, but the characters painted on the face of the gauge require the gauges be completely rescreened. Since this is an expensive process that most restorers are unwilling to pay for, the second solution is to increase the amount of light in the gauge cluster. Converting to brighter LED light allows the driver to see the print on the gauges better and nearly eliminates the need for the print to glow.

Summary

When you look at all of the things contributing to the decrease in the performance of the gauge lighting, converting your gauge lights to LED is the obvious solution. While the primary reason for converting your vintage instrument cluster to Led lights is for increased gauge visibility, there are several benefits that are equally important. For more information check out The Benefits of LED Conversion